VAPORKOTE COATING TECHNOLOGIES

VaporKote - Pioneering

Industrial Excellence

with

Cutting-Edge

Coating Innovations

VAPORKOTE COATING TECHNOLOGIES

VaporKote - Pioneering

Industrial Excellence

with Cutting-Edge

Coating Innovations

Address

1270 N Grove St Anaheim,

CA 92806

Give Us Call

(714) 632-8607

Send an email

sales@vaporkote.com

VaporKote Chronicles

How Our Expertise Transforms Equipment Lifespan

Get To Know VaporKote

At VaporKote, we don’t just shield metal; we safeguard legacies. With a rich history dating back to our establishment in 1987, we’ve seamlessly blended longevity, product quality, and technical prowess into the fabric of our existence.

Treatment TECHNOLOGIES

Top Rated Services In A Single Click

Machining Capabilities

Manufacturing large parts up to 68” diameter

Thermal

Boronizing high temperature cobalt base nozzles for increased wear protection

VK manufactured pump

wear rings

Shield against erosion

with precision boron coatings.

Aluminized heat

exchanger tubing

optimal protection against high temperature corrosion

Aluminized

Fasteners

for anti-galling properties

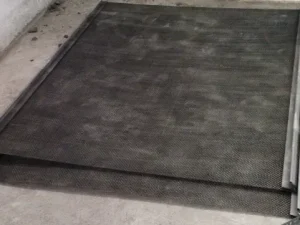

Wire cloth/reactor screen aluminized

For improved high temperature

service life

Close tolerance

machining capabilities

To meet customers-specific

requirements.

Boronized Pump

Impellers

All Surfaces Protected

We provide our services to a wide range of industries

VaporKote provides coating services to customers in a wide range of industries,

Address

1270 N Grove St Anaheim,

CA 92806

Give Us Call

(714) 632-8607

Send an email

sales@vaporkote.com